Green from Concept to Combustion

Emulsion systems can be described as either water-in-oil or conversely as oil-in-water.

The characteristics of the emulsifier required are different in each case.

The mechanisms tend to be opposite so what works as an emulsifier in one system can work as a demulsifier in the other.

Developed from our patented formulations, we look forward to expansion in this fast growing global market.

Worth $2.1Bn pa in 2021 and forecast to grow at +4% pa to $3.1Bn in 2030

SulNOx offers improved efficiencies for Demulsification

Following a program which included laboratory demonstration, small batch processing, and a laboratory scale proof of concept process, construction has now begun on the first pilot production plant close to the port of Durban in South Africa.

Sulnox has helped reduce the processing time and efficiency of recovering valuable oil from what is otherwise a toxic waste, with a lot of challenges and costs for safe disposal.

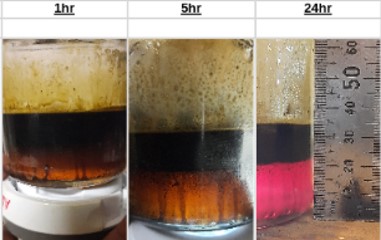

This reduction in the time it takes to separate the water and oil offers huge environmental benefits and significant opportunities for operators in the ports around the world.

Demulsification Outline

- Fresh fuel emulsion delivery arrives on site

- Emulsion is heated as required

- Berol 6446 is added

- Appropriate agitation is applied to achieve proper dispersion

- Product moves to settling tank system

- separation begins immediately

- results as low as 1.5% residual water in 3 hrs

Benefits and Advantages

Use of Berol 6446 in the process facilitates:

- faster separation of the phases

- more water removed from the oil phase

- more oil separated from the water phase

- more valuable oil for sale due to lower water content in oil

- Bureau Veritas tested 1.5% – 3.5% remaining water in final oil

- added lubricity in final oil from Berol 6446 remaining in oil

Fuel in Water Emulsion