REMNOX DIESEL FUEL CONDITIONER

IN A NUTSHELL

RemNOx Diesel Fuel Conditioner and RemNOx Petrol Conditioner have the unparalleled ability to disperse water in fuels (Particularly Diesel) to form long-term stable emulsions.

‘Conditioned’ fuel significantly alters burn profile allowing a cleaner and more complete combustion. Additionally, significant increase in lubricity improves performance and engine health.

“GAME CHANGING”

-WORLD LEADING LABORATORY

WHAT ARE THE BENEFITS?

Significant Savings

EN590 & EN228 Certified

Approved for use as a standard fuel thereby not voiding engine warranties.

Cost Effective

Significant savings with virtually no up-front capital cost or disruption to operations.

Environmental Benefits

Significant reductions in harmful pollutants, such as – COx, NOx, SOx, PM 2.5-10…

+31% Lubricity

Reduces engine wear thereby prolonging life. Less maintenance & servicing.

Diesel Bug Remedy

Eliminates Free-water contamination in fuel thereby eradicating Diesel Bug.

Antifreeze Properties

Significantly reduces the freezing point of Diesel to at least -20 degrees Celcius.

You can contact us to discuss the nature of your fuel usage and we can work together to evaluate fuel and maintenance savings, environmental benefits and more.

The importance of EN590 & EN228

- EN590 & EN228 defines the physical & chemical properties that all automotive diesel & petrol fuel must meet to be legally sold in the UK, the whole of the European Union, Croatia, Iceland, Norway and Switzerland. It is also a ‘Standard’ that is valued and recognised around the world.

- If by the addition of other additives, like Conditioner, the fuel does not then comply with EN590 & EN228, it becomes an illegal fuel and its use may negate an engine’s warranties.

- However, it has been certified by the internationally renowned Bureau Veritas, that a fuel containing RemNOx Fuel Conditioner remains fully compliant with EN590 & EN228. This certification is accepted in most of the world’s countries.

- This confirms that using RemNOx Fuel Conditioner in fuel will ensure that it remains a safe and legally acceptable fuel and its use cannot be claimed to breach the engine warranties.

EN 590 describes the physical, chemical and performance properties that all automotive diesel fuels must meet if they are to be sold in the UK, European Union, Croatia, Iceland, Norway and Switzerland

It is also a ‘Standard’ that is valued and recognised around the world.

EN590 was introduced to coincide with the development of new emissions standards across the European Union & the UK. The overall goal has been to reduce the sulphur content of diesel fuel (a major element of pollution. eg. acid rain). However, Sulphur has been used as a lubricant in most fuels and its role has to be replicated by another chemical if the Sulphur content is to be significantly reduced. RemNOx Fuel Conditioners provide that lubricity.

A user of fuel must utilise an accepted standard of fuel if they are to avoid engine damage or excessive wear. And importantly, not invalidate their engine manufacturer’s warranty.

Consequently, without a certified ‘Letter of No Objection’ from any engine’s particular manufacturer (basically giving permission to use a non-standard fuel), they cannot use a fuel which does not conform to an accepted Standard or a fuel whose formula has been altered or contaminated. The addition of chemical formulas to any fuel (like adding Fuel Conditioner) could then classify that fuel as non-standard or contaminated.

However, if the lubricity and combustion performance of a fuel with added Conditioner remains within the strict parameters of EN590, then it is considered a Standard Fuel and cannot legally breach the terms and conditions of a manufacturer’s engine warranty. This negates the need for obtaining ‘Letters of No Objection’ which are almost impossible to obtain.

Evidence that any fuel or treated fuel conforms to EN590 must be provided by a qualified and legally certified testing laboratory. Bureau Veritas, who have certified SulNOx conditioner, are accepted and acknowledged in 197 counties.

Even through the efficacy, safety, anti-pollutant and economic benefits of using SulNOx fuel products in fuel has been proven for many years, the difficulties of huge costs and the time required to elicit ‘Letters of No Objection’ from each and every engine manufacturer, has proven to be a serious hurdle. The Bureau Veritas certification as solved that deployment problem.

Because the use of RemNOx Fuel Condition is fully covered under the SulNOx Bureau Veritas certification, RemNOx can market its products without inherence and its use is fully insured.

Cost Effective

- RemNOx Fuel Conditioner is a patented, concentrated specialist chemical formula added to a fuel at any time prior to combustion, enhancing all aspects of an engines performance.

- Delivers significant fuel economy and reduces both inefficiencies and pollutants, with virtually no capital outlay or disruption to operating schedules.

- It only needs 1 part RemNOx Fuel Conditioner to 2,000 parts fuel. i.e. 1 litre treats 440 gallons of fuel

- RemNOx Fuel Conditioner provides for:

- Improves efficiency resulting in fuel savings of between 4% and 15%

- Remedies the problem of water in tanks and fuel systems.

- Remedies any Diesel Bug problems

- Ensures fuel systems and engines are kept of deposits

- Extends servicing intervals

- Ensures fuel lines and filters are kept clean

- Prolongs engine life

- Potential tax saving benefits

- Additionally, RemNOx Fuel Conditioner significantly reduces toxic emissions, such as Cox, NOx, Particulate Matter (eg ‘sooty’ deposits), SOx

Environmental Benefits

- It is now accepted that our Earth has an ever increasing problem with global warming and climate change. A significant contribution to such problems is attributed to man-made pollution and, in particular, the pollutants caused by the combustion of hydrocarbon fuels is the main focal point.

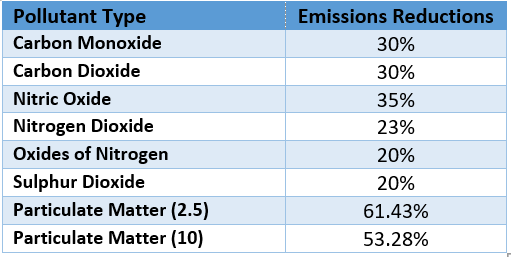

- The use of RemNOx Fuel Conditioner significantly reduces harmful exhaust pollutants caused by fuel combustion in engine and burners.

- Our antipollution technology has undergone a number of independent tests and long term experiments, both in the laboratory and in practical environments. Some of the contributing testers are:

- SGS Laboratories, UK

- Socotec Laboratories, UK

- Mobile HGVs at Millbrook

- Proving Ground, UK

- Unergy Laboratories, South Africa

The following statistics are an average guide to very significant results. However such results do vary, depending on differing types and condition of engines used and the various parameters of the testing conditions:

Lubricity

RemNOx Fuel Conditioner increases lubricity by over 30% as verified by Bureau Veritas.

There are numerous benefits to added lubricity resulting in significant financial savings:

- Improved combustion and efficiency

- Cleaner Fuel Systems and less corrosion

- Less engine & parts wear

- Iincreased engine life

- Reduced maintenance costs & required service intervals

- Ensures injector nozzles are kept of deposits

Find out more about lubricity as written by Jimmy Redman Jr, inventor of the products:

Everybody knows what a lubricant is, and we use lubricants to reduce friction in order to prevent

chaffing, scuffing and wear between two surfaces that are moving in relationship to one another.

Lubricity is the term used to rate the effectiveness of a lubricant, and a system of measuring this was

devised by applying a controlled amount of friction between two surfaces, using the lubricant under

test to protect these surfaces, and then measuring the amount of wear that occurs to rate that

lubricant’s performance.

The function of a lubricant is to prevent, or at least reduce, wear between two surfaces. The lubricity

test result is a reading of how much wear occurred during the test, or simply put “how much wear

the lubricant failed to prevent”.

It follows then that a lower score indicating less wear is more desirable than a higher score

indicating more wear.

Lubricants prevent or at least reduce wear, which in some instances can be extremely costly to

repair. Thus, the better a lubricant and the lower it is lubricity score, the more wear will be

prevented, and the greater the value of the costs of repair, that are reduced and thus saved.

Historically, or at least into the 70’s, fuels such as diesel were considered to have adequate inherent

lubricity for their use in engines without any additional lubricity improver’s.

This all began to change when Sulphur Oxides in exhaust gases were targeted for reduction as part

of the campaign to reduce harmful emissions, which rolled out globally and to this day, continue to

increase in severity. This is achieved primarily by reducing the sulphur content in the fuel itself and is

carried out at the refinery level.

The processes used to reduce the sulphur content in the fuel, further reduced the lubricity, due to

their effect on the properties of other constituents of the fuel. This essentially amplified the

worsening of lubricity caused by reducing the sulphur content.

Additives have become necessary in order to improve the lubricity of fuel, which has been subjected

to the processes of lowering the sulphur content.

This is done both by refineries themselves, and through the use of commercial, after market,

specialist additive suppliers.

Due to the superior lubricity inherent in a host of vegetable oils, these began to be introduced into

fuels distributed for use in diesel engines, in order to restore the lubricity levels.

This process continues to repeat, as fuels progress along the path of diesel from low sulphur diesel,

to very low sulphur diesel, to ultra-low sulphur diesel, and the percentages of vegetable oils is

increased each time.

This process is not without its issues, and new problems are found with each change.

The bottom line is that improving the lubricity of any level of fuel is going to improve the fuel,

reduce wear, and save money.

Improved lubricity also saves fuel.

It thus stands to reason that regardless of the grade of fuel used, significant improvements in the

lubricity of a fuel will reduce the friction in the engine and lead to significant improvements in fuel

consumption as well.

Diesel Bug Elimination

- ‘Diesel Bug’ is the name ascribed to microbial contamination within diesel fuel. When diesel contains -water at a temperature between 10° C and 40° C, then bacteria and funguses can cause microbial growth to occur.

- Bacterial and fungal spores commonly found in the soil can enter the fuel tank through vents on the storage system or by contamination during filling.

- The allowable presence in most brands of diesel of up to 7% biodiesel (which holds and attracts water more than fossil based diesels), also exacerbates the conditions for the growth of Diesel Bug.

- The presence of significant Diesel Bug contamination can be identified by:

- Fuel turns dark

- Shortened fuel-filter life

- Fuel degrades during operation

- Stench emanating from the fuel tank.

- Ruined fuel injectors (corrosion)

- More exhaust smoke than is usual

- Floating contaminants or ‘sludge’ in the tank

- Reduction in fuel economy

- RemNOx Fuel Conditioner obliterates Diesel Bug by simply eradicating any -water, by way of forcing its complete emulsification with the fuel, thereby removing the habitat of the Diesel Bug so that it can’t exist.

Antize Properties

Significant antize properties

- RemNOx Fuel Conditioner can very significantly reduce the zing point of Diesel to minus 20° Celsius or even much lower.

- In very cold weather and in traditionally cold climates, it is not unusual for diesel tanks and fuel lines to ze. In such cases it is also not unusual to see drivers lighting fires under their fuel tanks to get going. A practice that is not recommended!